Selenizza® SLN : a naturally occurring asphalt additive for producing high performance bituminous mixtures

Our product conforms to EN 13108-4 Appendix B Table B2

The additive Selenizza® SLN is compatible with all types of bitumen and its asphaltene content confers to bituminous mixes exceptional rheological and mechanical properties.

It can be blended directly with the hot bitumen in tanks, but usually, it is added during the asphalt mixing process (in the mixer for the discontinuous asphalt plants, or in the recycling ring for the continuous plants).

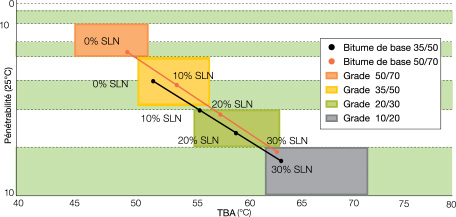

Depending on the added quantity of Selenizza SLN and on the characteristics of base bitumen as well, it is possible to obtain precise penetration and R&B softening point values of the resulting binder.

Its acidity index enhances the adherence of the constituents of mix asphalt. Selenizza® is completely and uniformly miscible with base bitumen. The resulting high performance asphalt mixes are homogenous and ensure better workability.

| Penetration à 25°C (1/10 mm) | EN 1426 | 0 - 1 |

| Softening point (R&B°C) | EN 1427 | 115 - 120 |

| Penetration Index (IP) | - | > 3,0 |

| Acidity Index (mg KOH/g) | EN 14104 | 3,5 |

| Density at 25°C (g/cm3) | EN ISO 3838 | 1,16 - 1,25 |

| Asphaltene content (wt %) | ASTM D2007-11 | > 50 |

| Mass loss at 163°C, 5 hours (%) | EN 13303 | 0,08 |

Selenizza® Usually supplied cold and solid in several forms:

Pellets with size range from 4 to 12mm packed in 0,8 - 1,4 tonnes bags.

Powder 0-5 mm packed in 15 kg fusing plastic bags

Tailor-made weighted bags could be manufactured on customer request depending on the total order amount.

Please download our brochure and our technical data sheet for more informations.